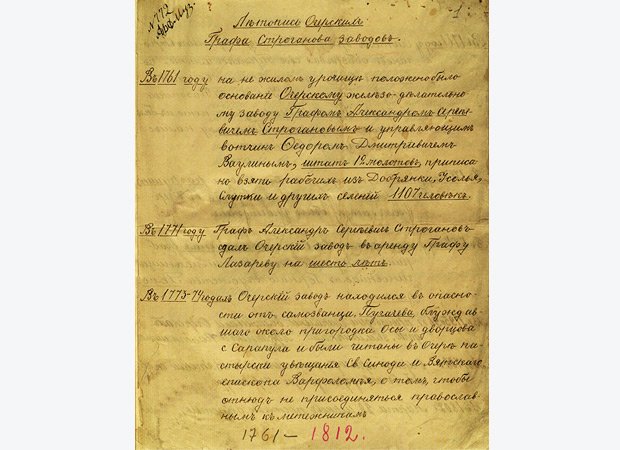

History

The responsibility for the development of the family business fell on the shoulders of 24-year-old Baron Alexander Sergeevich Stroganov.

By this time, the heir had received an excellent education, which included a serious course in studying industrial enterprises in Europe. In 1746, Alexander Sergeevich's eldest uncle, Alexander Grigorievich Stroganov, built the Yuzhno-Kama plant.

Based on his successful experience, Alexander Sergeevich accepted the offer of manager Fyodor Vaulin and decided to build a plant in the forest-rich Ocher areas. A large amount of charcoal was required for the forges of the hammer mill. The only thing left was to create a new city-plant in a remote corner of a huge estate.

A decision was made to build a plant. At the request of Alexander Sergeevich Stroganov, permission was received from Empress Elizabeth Petrovna to build an ironworks. By her decree of June 7, 1759, construction began on an uninhabited site five miles from the village of Luzhkovo, at the confluence of four small rivers: Ocher, Duzhkovka, Berezovka and Travnaya.

First, barracks for workers and houses for employees were built. Savin, a dam specialist from Dobryanka, was in charge of cutting down the forest and constructing the dam. Then they built the walls of the hammer factories and fur buildings, installed machine tools, furnaces for smelting cast iron and bloomery furnaces. A serf Alexei Pryadilshchikov from the village of Dubrovskoye was appointed for general supervision.

The dam took the most effort. At that time, it was one of the largest hydraulic structures in Urals. The earth for the dam was mined by hand: they dug it with shovels on the slope of Mount Kukuy and carried it on their backs, or transported it in wheelbarrows and carts.

Production began. The history of the plant dates back to this year.

Alexander Sergeevich Stroganov was informed that 4 hammers were put into operation, on which iron was forged. The cast iron from which the iron was produced was delivered from the Bilimbaevsky plant (now Sverdlovsk region) during the spring flood by rafting on barges along the Chusovaya and Kama rivers to the Taborskaya pier. There it was reloaded, and then serfs delivered it to the plant by horse-drawn transport.

A total of 181 people were employed at the plant, including servants, servants, craftsmen and workers.

Kopan' is a man-made canal connecting the Cheptsa and Ocher rivers.

At the beginning of the 19th century, the Ocher ironworks of Count Stroganov, which received energy through water, experienced energy difficulties. In order to more reliably replenish the Ocher pond with water, it was decided to move part of the water from Cheptsa into it using a deep trench.

This project was carried out by serfs in 1813-1814.

The new manager was appointed the district councilor Ignatiev. The Stroganovs entrusted him with the management of their entire estate as a man with great experience in mining and metallurgy.

Ignatiev drew up detailed plans for the work of the Ocher and Pavlovsk plants. The plans provided for the general production volumes, standards and wages for serf craftsmen, which depended on production costs and market prices for commercial iron.

Opening of a new sheet iron factory, where the production of tables, trays, boxes and other items was established. All of them were hand-made by talented Ocher craftsmen, had a unique ornament and were in demand.

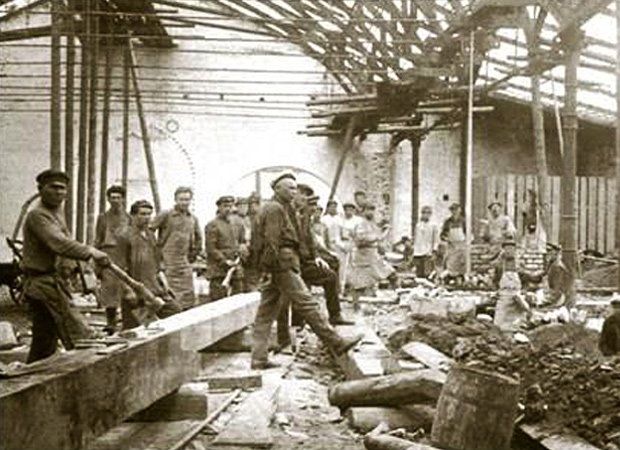

The beginning of the construction of stone workshops, including a bloomery, a turning shop, a tire-rolling shop and others. They were designed by A. Z. Komarov, one of the most talented architects of the Urals.

The layout took into account the organization of the production process, shortening the routes of movement of products, creating comfortable conditions for work and reducing costs.

The construction of the stone workshops was completed in 1844. The work done was difficult: the duration of the shift reached 16 hours or more. Misdemeanors and sabotage were severely punished.

In October 1909, news came from St. Petersburg about the Stroganovs' intention to close the Ochersky and Pavlovsky factories in November 1910. At the cost of considerable effort, they managed to delay the closure for six months.

On May 21, 1911, the Ocher and Pavlovsky factories were closed as unprofitable. In order to survive, people began to make various handicrafts and went to distant lands to earn money.

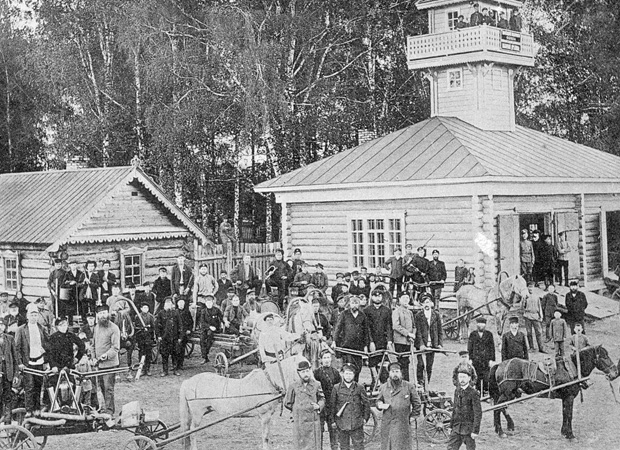

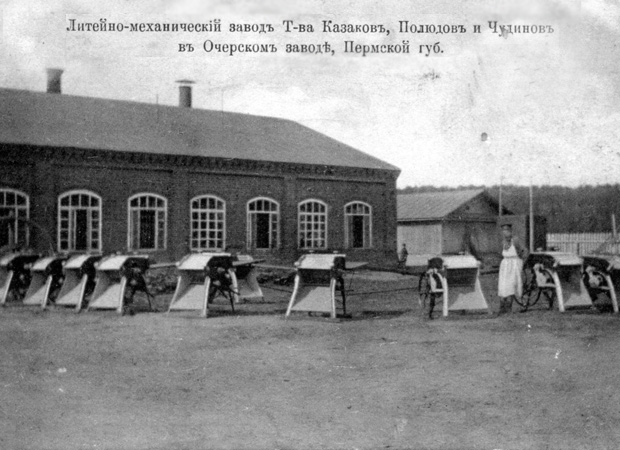

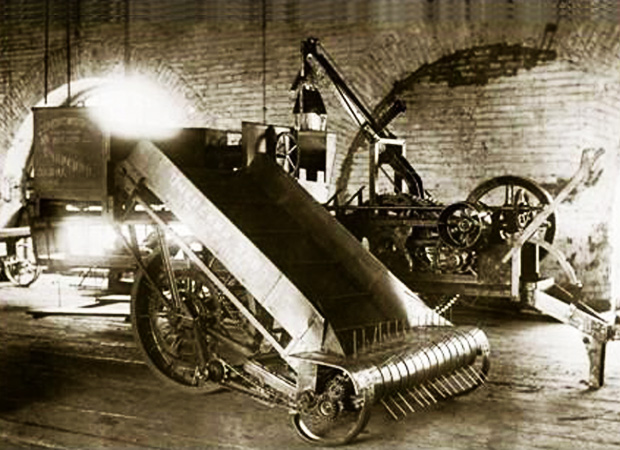

In 1913, the buildings of the Ocher plant were rented by the Okhansk zemstvo, which created a model workshop for the production of agricultural machinery and weapons: threshing machines, shells, grenades, axles and bushings for artillery carts, diaphragms and shrapnel, wire cutting shears, yews, anvils, etc.

On October 1, 1922, the enterprise was named State Plant No. 5, where the production of agricultural machinery was established.

The production volume of the now state plant was 50 units per month. In addition, the production of manure spreaders, hay presses, flax spreaders, flax crushers, flax threshers, hydraulic pumps, straw cutters and other products for agriculture was established.

In 1922, American Fordson tractors drove along Torgovaya Street (now Lenin Street), a rally was organized near the district store. Currently, there is a memorial plaque there, reminding us of those events.

During the 1930s and 1940s, the first products for oil extraction were launched, including bitumen cooking boilers, crawler trucks, rocking machines, drilling equipment, and bits. During the Great Patriotic War, the production of military-industrial complex products (120-mm mines) was launched.

During the 1950s–1990s, the range of engineering products for oil industry workers was expanded to include pipe layers, trawl suspensions, rod carriers, and bulldozers.

In the 1970s and 1980s, the plant was actively reconstructed, a second workshop for the production of pump rods was built.

Thanks to this, Ocher was gasified, since the equipment introduced at the enterprise operated on gas. The working day was at least 12 hours.

According to the plan, the plant was supposed to produce a million deep-well pump rods per year.

In the 1980s, the plant began to solve housing problems, and construction of houses for plant workers began. The more they built, the more new housing was needed.

In 1984, about 1,500 people worked at the plant. For many, the enterprise became a family, with entire dynasties working there.

The 1990s were a time of trouble for the plant, production volumes fell sharply, and there were constant job cuts. Many doubted that the plant would survive. Despite this, the construction of residential buildings continued.

However, due to a lack of funds, many projects had to be closed, and a number of buildings remained unfinished.

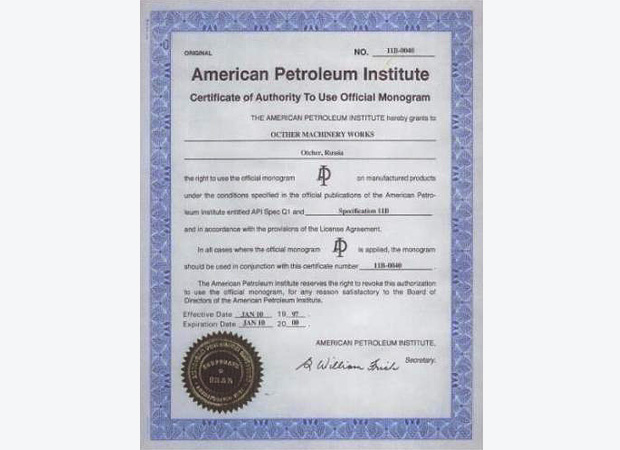

The plant becomes the only enterprise in Russia whose production of oilfield equipment has been awarded the international Quality Certificate of the American Petroleum Institute (API), as well as the certificate of the European Organization for Standardization ISO 9001:1994 (E).

This has allowed the expansion of the sales market for the plant's products.

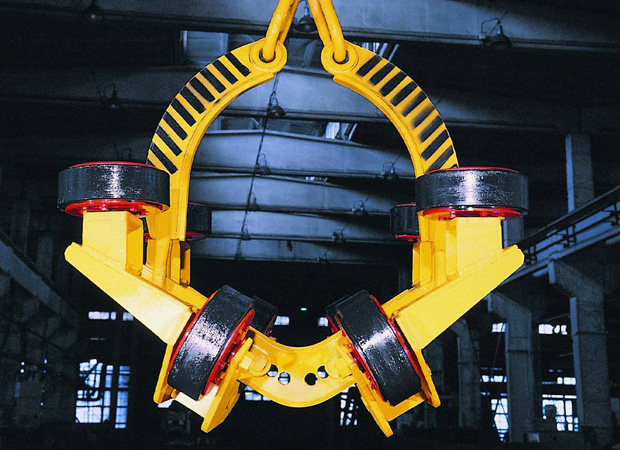

A workshop for repairing railway wagon wheel sets, "Wagon Wheel Workshops", has been created.

The VKM workshop of OAO OMP has become one of the first private VKMs in Russia to receive the right to repair wheel sets for the main railways of the Russian Federation.

After a 13-year shutdown, the metalworking shop has resumed operations. Production was opened as part of cooperation with the Uralmash enterprise.

OMP's own development has been implemented — an exclusive technology for restoring pump rods.

In just six months of cooperation with Udmurtneft OJSC (a division of Rosneft Oil Company OJSC), the order for restoring used pump rods that have undergone a full technological production cycle has grown from 1,670 to 3,500 pieces.

Ocher Machine-Building Plant celebrates its 250th anniversary.

History and modernity

The personnel department is headed by a hereditary plant worker A. V. Solodnikov, who took up the baton. Work is constantly underway to prepare and train workers for specialties (crane operator, turner, welder, fitter, slinger, heat treatment specialist, foundry worker, blacksmith). The department closely cooperates with the Employment Center, places advertisements in the media. Labor cards for each employee are in the archive of the plant's HR department and are subject to permanent storage. The plant's personnel department is the largest in the Ocher district.

Work with youth

Graduates of Ocher schools were plunged headlong into the thick of the real life of our city, into the everyday life of the Ocher Machine-Building Plant. The plant shows what real work is at a heavy engineering enterprise. These workers' hands are in oil and fuel oil, huge machines, high temperatures and the hum of operating equipment.

In Soviet times, such excursions to enterprises were traditional. Then they were banned by the requirements of safety. Today, with the observance of safety measures and preliminary instructions, this has become possible again. The first were the 11th grade students of Secondary School No.3.

The organizers of the excursions hope that the youth of Ochyor will not be afraid of the difficulties associated with working at the plant, but will return to their native Ochyor after receiving an education at post-school universities in order to continue the labor traditions of the plant dynasties of their ancestors. Summer holidays The Ochyor Machine-Building Plant accepts teenagers from the age of 14 for seasonal work — gardening, design.

We remember you, front-line plant workers

Traditionally, elderly people who devoted most of their working life to their native enterprise, students of all schools, and city residents gather at the memorial in honor of the plant workers who died on the fronts of the Great Patriotic War.

Veterans are congratulated on the holiday and thanked for their selfless work by representatives of the plant administration services, the military commissar of the Ocher district, the rector of the Church of the Archangel Michael and the city administration, school students.

The Ocher delegation, including our plant worker, veteran of the Great Patriotic War F. F. Yemelyanov, participated in the ceremonial transfer of the "Eternal Flame" with the whole country on May 8 at the Victory Memorial in Perm.

The plant workers annually lay memorial garlands in memory of the feat of the Ocher plant workers who died during the Great Patriotic War. It was from the plant that the best personnel, professional workers, went to the front during the war. A total of more than 800 people. The watch of memory is conducted by employees of the OMP museum and members of the OMP veterans council.

The oldest enterprise in the Urals is turning 255 years old! The machine builders have approached another historical milestone with dignity, on a production upswing: the plant is operating, providing work for about 1,000 residents of the region, products with the OMP brand are in demand in the domestic and world markets, the business ties of the enterprise are expanding, volumes and orders are growing.

The plant workers, in the best traditions of their predecessors, are meeting the anniversary date with enthusiasm and writing worthy pages in the history of OMP with the work of the plant workers.

One of the leading sectors of the economy of the Russian Federation, the Western Urals, and the Ochersky District has been created.

The plant's rod production practically works for the entire oil industry of Russia. It meets international standards and attracts with an acceptable price.

Professionals

For the first time in the post-Soviet period of development, the plant has concluded contracts for the supply of rods with foreign companies: - in 2016 with OOO "BUDMAKS-INDUSTRY" - 2017 with OOO "Sheaharvestfreezone", DAP "Elemir", OOO "TotalRodConcepts" - 2018 "HazarNebitHyzmatlary" - 2020 PT. INTERDRIL INDONESIA, as well as South American countries such as Brazil, Argentina and European Serbia. At the beginning of the 2nd quarter, the first batch was shipped. The brand is held - "Made at OMP". It is expected to increase the supply volumes. 75 thousand pieces are produced monthly.

The plant has been repairing rods since 2005. The method of repairing 7200 mm long rods remains a permanent production task. In addition, oil workers are interested in repair rods using the "rolling" method from a larger to a smaller diameter, introduced in 2011.

In 2015, the production of 13 mm diameter rods was launched. The development of the KD-TD, tooling, and main tool was carried out by the plant's engineering and technical staff, and manufactured by plant specialists. Tests were conducted in Russian oil wells. A lightweight type was approved, and orders from consumers were received. This type of rod is under the control of the President of Tatneft.

At its own expense, the company solved one of the serious problems: heat and hot water supply, by implementing a set of measures. In 2 years, the DHW heating system was completely replaced in all production areas, the main buildings-walls were insulated, windows were replaced, and workshops were equipped with metering devices. The plant's utility costs for this type of service were significantly reduced.

Traditionally, the work of the machine-building plant's professionals was appreciated at the highest level. A group of plant employees were deservedly awarded the Certificate of Honor and Gratitude of the Ministry of Industry and Trade of the Russian Federation.

Professional skills competitions have already become traditional at the plant. Every year the number of participants increases, new professions are added, representatives of which have never been seen in competitions before, incentives are good to prove themselves as workers and, of course, to make a name for themselves. Winners are entered on the enterprise's "Honor Board", plus they receive an additional payment to their salary during the year, and of course, the organizers do not skimp on valuable gifts - regardless of the place taken, they are presented to all winners. Usually, competitions are timed to coincide with the professional holiday of machine builders.

People know exactly what to do

Perm Region Governor Maxim Reshetnikov paid a working visit to Ocher, including OAO Ocher Machine Building Plant.

A well-structured diversification of production was noted. Products are supplied to the largest oil companies in Russia, the United States and other countries.

The regional authorities are working to create favorable conditions for the development of the industrial potential of the Kama region — all leading industries without exception have applied with investment projects. The investment program at OMP is designed for five years. This year, repairs to thermal unit No. 2 are planned, equipment and components are being purchased.

The enterprise is being modernized. Since 2011, metal structures have been manufactured here.

Turner-engineer-director-minister-Hero of Russia

"There is no industry more important in life - everything in the world rests on it...". There is no doubt that the history of the plant has a worthy continuation, my fellow countrymen — Ochertsev have good prospects for the future. I was convinced of this personally, having visited the plant and talked with the management, workers, I felt real pride for us, dear machine builders.

This is the labor path and recognition of services to the country of a native of Ocher, a former plant worker Ivan Mikhailovich Kamenskikh, now Deputy General Director of the State Corporation "Rosatom".

At the beginning of July, in the Kremlin, the President of the Russian Federation presented our fellow countryman with the Star of Hero of Russia. I. M. Kamenskikh has been working in the nuclear energy industry for more than 40 years, developing its various areas, supervising the construction of nuclear power plants that Russia built abroad.

For the first time in recent years, the newly minted Hero of Russia I. M. Kamenskikh recently went on vacation from Moscow to dear Ocher.

Fiberglass pump rods

Development of new products began on the site of the dismantled automatic Kyiv line for mechanical processing of rods.

Modernization of production

There are three production areas at the plant: production of oilfield equipment, production of metal structures, production of fiberglass rods, which was mastered last year in 2022, in 2023 it was separated into a separate area and located on the premises of the former wagon wheel workshop. All three areas work at a rapid pace in a 24/7 flexible work schedule. The products are in demand by oil, gas and mechanical engineering industries. In connection with this, the volume of production is constantly increasing. In 2023, work was carried out to modernize production.

The investment program approved by the shareholders of the enterprise consists of more than 30 units of metalworking equipment, more than 10 units of special - unique equipment, significant funds were allocated for the repair of buildings, structures and highways on the territory. The second stage of the road for the movement of trucks and the territory was asphalted.

The plant's technical specialists are working on launching serial production of a new area of activity - the manufacture of components for the construction of buildings.

This year, we fully launched the loading and unloading platform for railway cars in the city of Vereshchagino for finished products.

We also paid serious attention to the modernization of the motor transport shop of our subsidiary and purchased special-purpose vehicles, heavy-duty vehicles for the delivery of finished products, passenger cars and medium-tonnage vehicles.

Equipment for the production of fiberglass pump rods was launched. More than 50 people who have been trained at the plant work in the area. Fiberglass pump rods are products used in rod columns for oil production from ultra-deep wells or from highly corrosive wells.

In parallel, to master the production of fiberglass pump rods, we are developing a section for mechanical processing of rod heads. For this purpose, we purchased and launched 10 modern CNC machines. Experimental work is underway on the composition of the components of the composite adhesive. The main customers of the SHNS since mid-2022 are — Kazakhstan "Neftegazstroykontrakt" (Self-pickup), — Almetyevsk "NKT-Service"; — "TatneftSnab" Leninogorsk; — "Tatneft-NKS Service".

The project for applying a wear-resistant coating to the surface of rod couplings is at the stage of 90% readiness. The coating is innovative, must comply with Russian and foreign standards.

At the request of the consumer, "new products" have been developed and introduced into the long-term serial production Wellhead seals with a safety device and a quick-release connection (BRS for NKT 60 and NKT 73).

Modernization and technical re-equipment, development of new technologies and new products, introduction of their production - all these are essential components of mechanical engineering.

Since the 4th quarter of 2024, repairs have been carried out on Thermal Unit No. 1. Dismantling to the underground part of the foundation and installation of new equipment is carried out by the plant and the Contractor. Completion of the work is planned for 2025.

On June 10, 2023, as part of the unique patriotic festival "Perm-300", a large-scale exhibition was opened in workshop No. 5 of the socio-cultural space "Shpagin Plant". The symbolic start of the event was given by the whistle of the "Victory Echelon" arriving at the Perm-1 railway station. This train, pulled by a steam locomotive, worked during the Great Patriotic War and in the post-war period.

The OMP Museum took part in organizing this exhibition. Our military products: mines, F-1 grenades, a model of a mortar, accompanying historical documentation have taken their rightful place and will be displayed by decision of Governor D. N. Makhonin until December 31, 2026.

In order to increase the durability of the MS rod couplings and their corrosion resistance, as a result of cooperation with the State Scientific Institution "Institute of Powder Metallurgy", it was possible to introduce gas-flame spraying (metal coating - a method based on feeding the material in the form of nickel-based powder through a sprayer to a nozzle tip, in which, concentric with the channel for the passage of the material, channels are made for feeding the combustible mixture into the heating zone. When the mixture burns, a ring flame is formed that heats the sprayed material to a temperature close to its melting point of 1000 ˚С - 1100 ˚С* and transfers particles to the sprayed surface). The introduction into production was preceded by: development of technical specifications, research work at the "Institute of Powder Metallurgy", an order for the manufacture of the necessary equipment and development of a technological process, acceptance of equipment and technological process by plant specialists, training of engineering and technical workers and service personnel. Experimental work led to good results.

USK new production "Building structures section"

The plant's specialists are working on launching serial production of a new line of business — manufacturing components for building construction.

To open a new line of business "Building structures section", the production area was prepared, administrative and utility rooms were renovated, and special equipment was installed. Employees were appointed and recruited to the section. Design documentation for tooling, etc. was developed. The first order was being developed and shipment to the consumer picked up speed: "SHCHUR" — Corner stripping panel, designed to form internal corners and connect formwork at right angles.

Following contractual orders of the "PERI" enterprise "Univilka", serves as a support for I-beams; Corner element "UG"; "Two-level brace" is designed to install formwork panels in the design position, adjust and perceive the wind load; "Leveling beam" BV. New orders will appear.

In May, all plant workers underwent a medical examination by Perm specialists.