Calibrated steel circle

JSC Ocher Machine-Building Plant supplies calibrated circle of its own production according to GOST 14955-77 “Quality round steel with special surface finish”.

Special surface finish is achieved by removal of the surface layer of metal. The initial raw material is hot-rolled steel from our partners metallurgical enterprises of the Urals. Available “silversilver” from medium carbon and alloy steels.

| Range of rod diameter, mm | 17 - 58 | Rolled product curvature, mm/m | less than 1 |

| Range of rod length, mm | 3000 - 10000 | Diameter tolerance | A according to GOST 2590-2006 |

| Tensile strength, MPa | to 950 | Roundness, mm | less than 0,05 |

| Hardness | less than HB 300 | Roughness | less than 25-50 mcr |

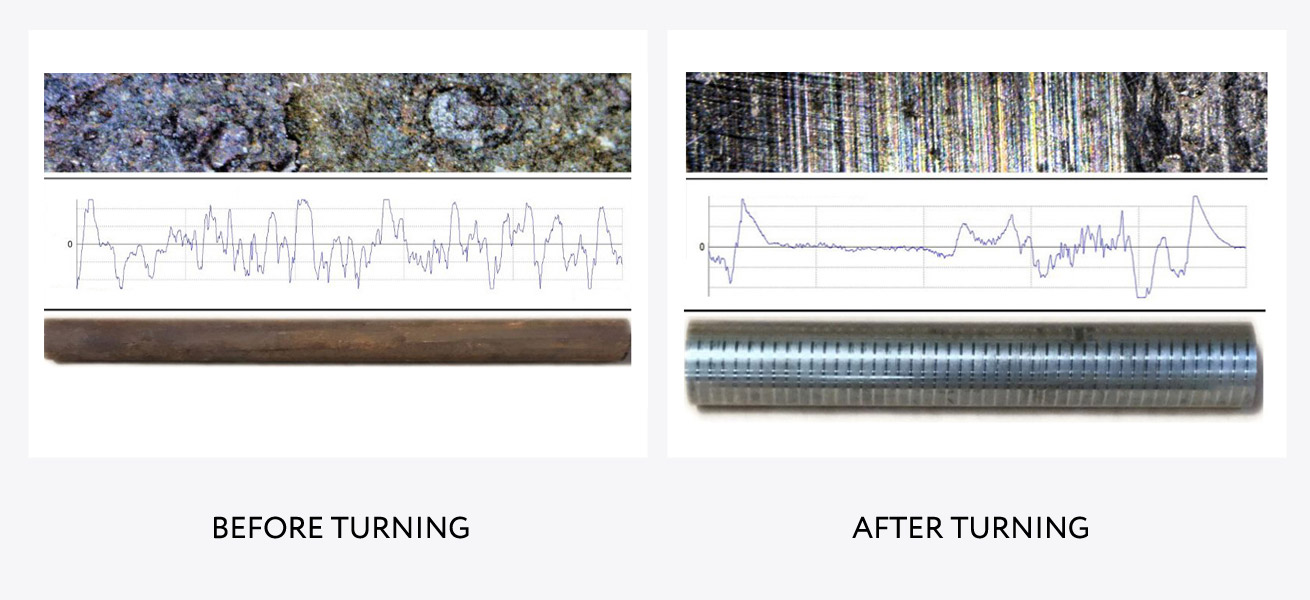

Turning of rolled products is carried out on modern centerless lathes, according to the scheme from bar to bar.

| Range of diameter, mm | 10 - 48 |

| Range of lengths, mm | 2000 - 9500 |

| Cutting depth per side, mm | 0,5 – 1,5 |

| Diameter tolerance | to h11 |

| Roundness, mm | less than 0,03 |

| Roughness | less than 6,3 - 3,2 mcr, depending on material |

- Defective decarburized surface layer is removed;

- Turned bars have tighter dimensions and roundness tolerances;

- Better straightness than the original hot-rolled coil.

Cold-rolled steel (silversmithing) can be used in most industries for direct manufacturing of parts and products.

- We cut rolled steel to the customer's size;

- The saws guarantee an immaculately clean cut without burrs;

- Chamfering on request.

JSC Ocher Machine-Building Plant has unique equipment that allows heat treatment of bars up to 12 meters long.

We are ready to offer heat treatment of both hot-rolled and turned bars, which includes hardening, tempering or normalization.

We guarantee high quality of finished products by means of non-destructive testing performed with the help of flaw detectors that detect both surface and internal defects.

OMZ's own laboratory: conducts mechanical tests, metallographic and chemical analyses of steels.

Cold-rolled bars are usually tested for compliance with GOST14955-77 and ASTM A 108.

- Labeling according to GOST 7566-94 “Metal Products. Acceptance, marking, packing, transportation and storage”;

- Marking at the customer's request.

Steel with special surface finish can be covered with corrosion-preventing grease or anticorrosion paper; packed in non-woven cloth or linoleum; packed in bundles with strapping or in wooden crates.

Need a cost estimate?

Leave a request on the website and we will contact you for a preliminary estimate

Application sent!

We will contact you for a preliminary estimate.