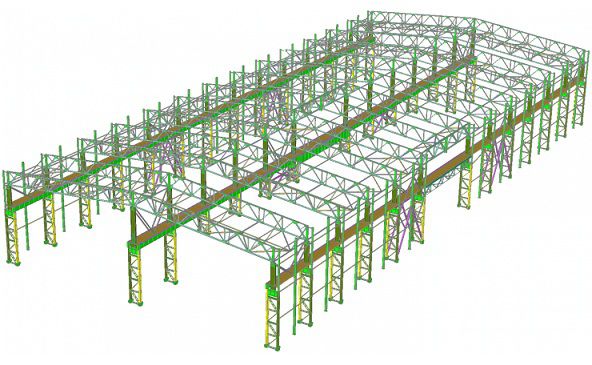

Metal Structures of Houses and Engineering Buildings

1. Light weight.

The lightness of metal structures achieved due to the steel strength, is one of their key advantages. Constructions made of other building materials are much heavier. Moreover, the bigger a building bay, the more significant is the difference in the weight of bearing structures that can increase tenfold. Such a difference in the weight of bearing structures affects the foundations of the object. After all, everybody knows that the lighter the frame, the simpler and cheaper the foundation.

2. Fast Construction Period.

The use of metal structures allows to build a house or a structure of almost any shape and configuration quickly, qualitatively and relatively cheaply. In the market economy conditions, the time factor in the implementation of investment projects in construction plays a crucial role and directly affects the profitability and payback time of investments. In terms of time, metal structures are hands-down winners in comparison with other construction technologies.

3. High degree of factory readiness.

Metal structures are produced at the plant that has high-performance equipment, input quality control of rolled metal products and associated materials, quality control of finished products, etc. This minimizes the risks of defects and reduces the timing of metal structures production and, accordingly, of erection of the facility.

4. Mobility.

The undeniable advantage of metal structures is their mobility. Often in the process of construction the need to make some alterations to the project arises. When using metal structures, there is an opportunity to react promptly to the wishes of a customer during (in some cases even after) the installation, when it is necessary to make alterations to the project. The mobility of metal structures is revealed in another way, when it is necessary to transfer an object to a new location. In cases of warehouses, hangars and small industrial premises, the transfer can be carried out quickly, accurately and without big problems.

5. Protection of metal structures.

Galvanization. Galvanized metal structures offer excellent hygienic properties; galvanized coating provides the best anticorrosion protection of metal structures and does not require finishing painting for a long time. There are two methods of galvanizing metal structures: hot galvanizing consists in the immersion of ready-made structural elements into zinc pots, and cold galvanizing consists in the application of zinc-rich coatings on finished metal structures.

The application of the cold galvanizing method has a number of undeniable advantages over hot galvanizing:

• no restrictions on the size of galvanized surfaces;

• the ability to prepare the surface on site;

• easy weldability of the structures coated with the composition for cold galvanizing;

• the possibility to galvanize welded joints on site;

• ease of repair of damaged (including damage during transportation and installation) zinc-coated areas;

• the possibility to galvanize over a wide temperature range from -20 to +40 ° C;

• obtaining flexible coating that can bear both mechanical deformation and thermal expansion and contraction over a wide range of temperatures;

• high adhesion of zinc coating with paintwork materials, including powder paints;

• the possibility to galvanize without subcontracting and in any way (by immersion in the composition, with a brush, a roller, a sprayer).

We offer a large variety of zinc-rich coatings for cold galvanizing:

• ZINOTAN®, a one-component poly-urethane blend, hardened by air moisture;

• ZINOL®, ZINOL-SVтм, a one-component composition based on a high-molecular thermoplastic polymer;

• TsVES®, TsVES-MO, a series of two-component silicone-based blends;

• ZINEP®, a two-component epoxy-based primer;

• ZINOTHERM®, a thermal-resistant one-component silicone-based blend;

• ZINMASTIC®, a series of spackling pastes.

As finishing coats for zinc-rich paints, blends based on aluminum powder and micaceous iron oxide are used: ALPOL®, ALUMOTAN®, ALUMOTHERM®, PAES® and based on micaceous iron oxide: FERROTAN®, IZOLEP-mio®.

Our company has modern equipment and extensive experience in the protection of metal structures by the method of cold galvanizing with the use of zinc-rich and aluminum-rich compositions: ZINOL, ZINOTAN, ALPOL, ALUMOTAN.

Low fire-resistance. Steel at the temperature of 200 ° C begins to lose its modulus of elasticity, and at the temperature of 600 ° C the steel changes into the plastic state. Therefore, metal structures of fire-prone buildings (warehouses with combustible or flammable materials, residential and public buildings) must be protected with fire-resistant lining (concrete, ceramics, special coatings, etc.).