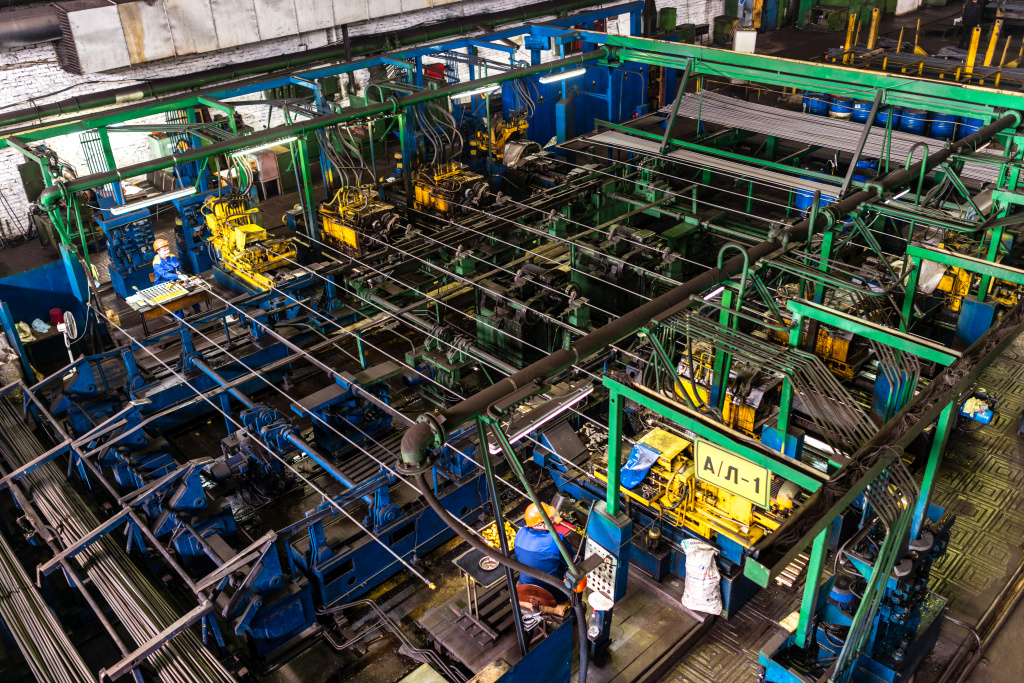

Oil Production Shop

Oil production is manufactured in the main production building, which consists of 6 aisles with a total area of 27,000 sq. m., four of which are occupied by the rod production shop.

About 300 people currently work in this shop. All workers of the shop are qualified and graded according to the skills they need in the technological process. The main part of the equipment is designed for the production of sucker rods and couplings for them. The shop is aimed at producing 1 million sucker rods per year.

The shop is equipped with the following lifting equipment:

• Overhead Cranes.

• Bracket-swing Cranes.

The shop uses process equipment of the following groups:

• Turning, including the ones with computerized numerical control;

• Vertical turning;

• Milling;

• Drilling;

• Boring, including the ones with computerized numerical control;

• Grinding;

• Broaching;

• Gear-making.

On turning lathes, operations are performed on machining cylindrical, conical, formed surfaces; boring cylindrical and conical holes; machining end surfaces; cutting male and female threads, including conical threads; it is also possible to drill, coredrill and ream holes; cut and trim parts, and so on. Boring machines have spindle diameter up to 160 mm. The dimensions of the table in the machining center are 800x800 mm. It it possible to process body parts on it with overall dimensions of 1600x1800x1400. You can bore, drill, coredrill, ream holes, mill surfaces with a class of accuracy up to 8 and a roughness parameter up to Ra = 2.5.

Gear-hobbing machines are used for cutting cylindrical spur and helical gears with a diameter up to 800 mm and a module up to 10 mm. A broaching machine is used for internal broaching. It is also possible to make splined bores and key holes. Milling machines allow to machine external and internal surfaces of various configurations, and to cut through grooves. The maximum size of parts for machining on milling machines is 320x1250x200. It is possible to make complex parts on milling machines with computerized numerical control. A circular grinding machine allows to machine parts with diameters of 40 – 400 mm and length up to 1800 mm. A surface-grinding machine allows to grind flat surfaces of parts with the periphery of a straight wheel. The biggest possible dimensions of a grinded part are 320x1000x400 mm. Splining machines allow to mill straight-sided and involute splines. The biggest possible diameter of a machined part is 150 mm, the length – 1000 mm.

The mechanical area is located in the 5th aisle of the main production building and occupies an area of about 4,500 sq. m. About 100 people currently work in this area.