Pipe Supports

Pipe supports are an essential component of pipeline of any kind. Depending on their purpose, pipe supports can be anchor-type, flexible, sliding and hanger-type. Besides, according to the pipelining method, supports are subdivided into above-ground and subsurface. Depending on the pipelining method, different types of waterproofing for the pipes can be used – galvanized or polyethylene coating. For isolated pipelines, a special design, "anchor-type urethane-foam support", with a coating of urethane-foam insulation, is developed.

Anchor-type pipe supports are made according to the following GOST standards:

• OST 36-146-88 "Steel Support of Process Piping";

• OST 34.10.610-93 - 34.10.745-93;

• GOST 14911-82 (OST 36-94-83) "Steel Piping Details. Pipe Flexible Supports";

• GOST 16127-70 "Steel Piping Details. Hangers. Types and Principal Dimensions";

• Series 4.903-10 Designs 4, 5, 6;

• Series 5.903-12 Designs 7-95, Designs 8-95, Designs 6-95;

• Series 5.900-7 Designs 0,1,4 (А14Б type);

• Series 313 ТС-008.000;

• НТС 65-06 Design 1 Flexible and Anchor-type Urethane-foam Pipe Supports.

Anchor-type pipe supports are designed to securely fasten the structure of the process pipeline in a given position in the systems of above-ground and subsurface pipelining. They bear and compensate for loads from temperature, vibration, pulsation and pressure change. It is necessary to install compensators taking loads between the supports. Special attention is paid to this when laying pipelines in the northern regions of the Polar Circle, where regular wide temperature fluctuations can seriously shorten the service durability of pipes. Anchor-type pipe support is installed on the pipeline with clamps or welded. When using pipe saddles, stop bars are welded to the pipe to prevent slippage.

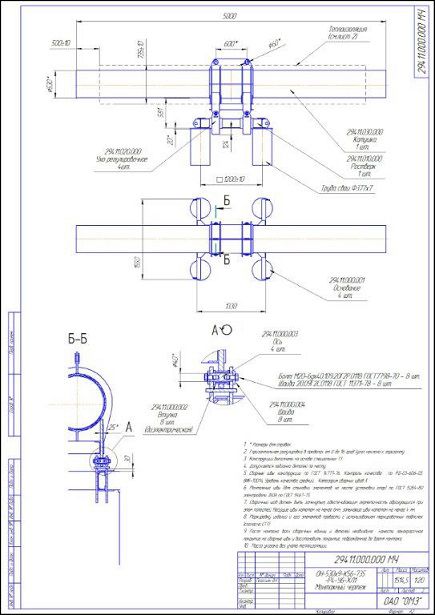

Supports are of the following structure types:

• single-clamp anchor-type pipe support;

• double-clamp;

• frontal two- and four-shoulder;

• weld support;

• support with weld shoulders;

• loop-type supports.

During the installation of the pipeline, the supports are installed on metal structures or attached to embedded parts of reinforced concrete framings. To protect pipelines from the harmful effect of ground currents, it is possible for all types of supports to be designed with electrically insulating gaskets.

The main elements of a anchor-type pipe support are joint sleeves made of a steel pipe, steel flange, urethane-foam insulation, galvanized or polyethylene coating, shrinkable thermal cover for damp-proofing.

Pipe Supports are most often made of carbon steel. In the design documentation, along with the type and schedule-size of the products, the steel grade is indicated, as for the northern regions low-alloy frost-proof steels, 09Г2С and 17Г1С, are used. The anchor-type urethane-foam support is also produced at our plant.

The production of supports in our enterprise includes the entire production cycle with obligatory input inspection of basic and welding materials. Anchor-type pipe supports are produced on modern equipment by well-qualified personnel and under the supervision of engineering manpower.

The plant produces anchor-type pipe supports in accordance with GOST and OST standards, data sheets and series, and customers' individual drawings and requirements.

The cost of structures for custom manufacturing is calculated individually, depending on the technical characteristics of the supports and the order volume.